An extruder line up designed specifically for the medical market.

The Elite includes easy to swap barrels (.5 in. - 1 in.) with stainless wipe down surfaces, unique wire management, and more

The Reflow is engineered for medical reflow materials. It includes a polished stainless construction, our smallest form factor, and screw designed for processing PEBA, Nylon, and TPU.

The Flex includes easy to swap barrels (.5 in. - 1 in., .75 in. - 1.25 in., or 1 in. - 1.50 in.), unique wire management, and more.

The Fluoro includes a special 27:1 barrel and screw length for melt temperature uniformity, high temp capabilities, corrosion resistant, and more.

The Med-Ex includes our core design with direct drive, pressure control, and more.

The Silicone includes a one piece barrel , hinged opening feed section, feed roll cooling, and more.

The Quench Tank was engineered and built in-house and designed to be part of a precision tubing line. Includes stainless design, precision control, and more.

The Take Up/ Pay Off was engineered and built in-house and designed for braided catheter tubing applications.

Extruders

Transparent Lead Times

We maintain strong relationships with vendors and proactively stock essential components to ensure that our custom extruders are delivered in the shortest possible time. This guarantees that our clients receive top-quality equipment without unexpected delays.

1/2 in - 12 in.

Built to your unique

specifications

User focused designs & features

Robust

Serviceable

Ready to run

2.5" 24:1 Extruder

2" 24:1 Post Co-Extruder

2.5" Silicone Extruder

Single-screw Extruders & Extrusion Systems for Plastic, Rubber, & Silicone.

1.5" 24:1 &

3" 30:1 Profiles Extruders

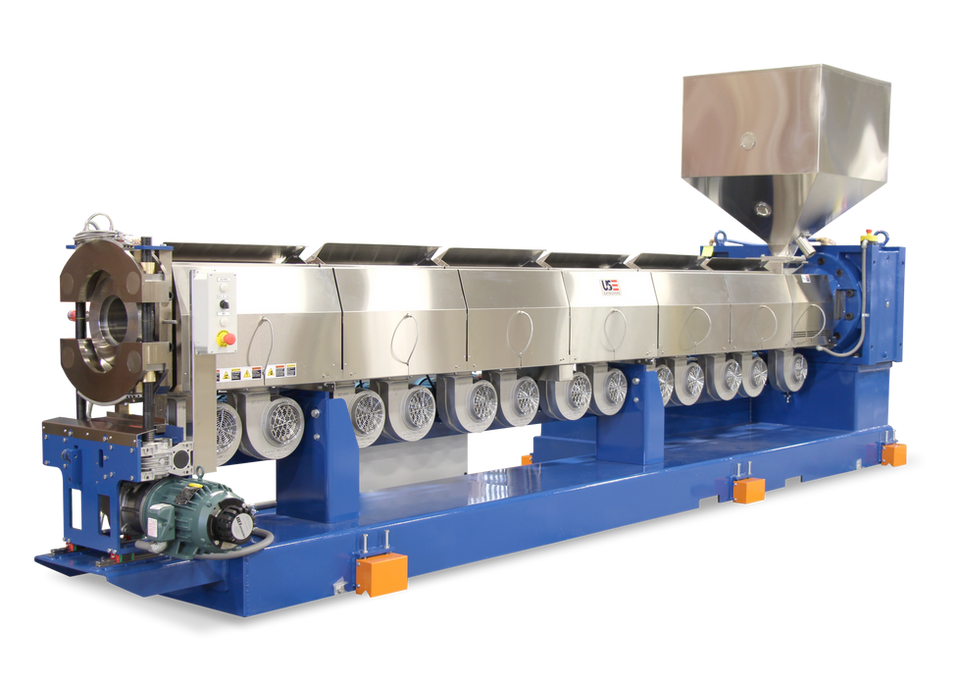

175MM 30: 1 Recycling Extruder

with RAM Stuffer

Extrusion Systems

Fully integrated extrusion lines with factory acceptance testing at US Extruders and site acceptance testing at customer's facility.

MED-EX Micro Extrusion Line